Asun is the first company in Singapore specializing in manufacturing of disposable medical masks, surgical masks and customized personal protective masks.

In the context of the spread of the global coronavirus epidemic, masks have become a strategic protective asset for countries around the world. In the face of the huge demand from the general public and public service sectors such as the medical and healthcare systems, the supply and reserve of all kinds of masks are seriously insufficient. However, Singapore has no production capacity of masks domestically and completely relies on overseas procurement. In the face of the global shortage of masks, the quantity and quality of overseas procurement cannot be guaranteed, and a large number of imported unqualified masks are crowding into the market.

In order to meet the needs of the domestic medical and healthcare systems during the emergency period and provide qualified masks with quality assurance to the public, Asun International decided to invest in the construction of a local mask manufacturing facility. The project was approved in March 2020. After two months of investigation, research and planning, the company purchased the world's most advanced automatic mask production equipment, established reliable supply relationships with foreign high-quality raw material suppliers, and set up a high-standard production facility.

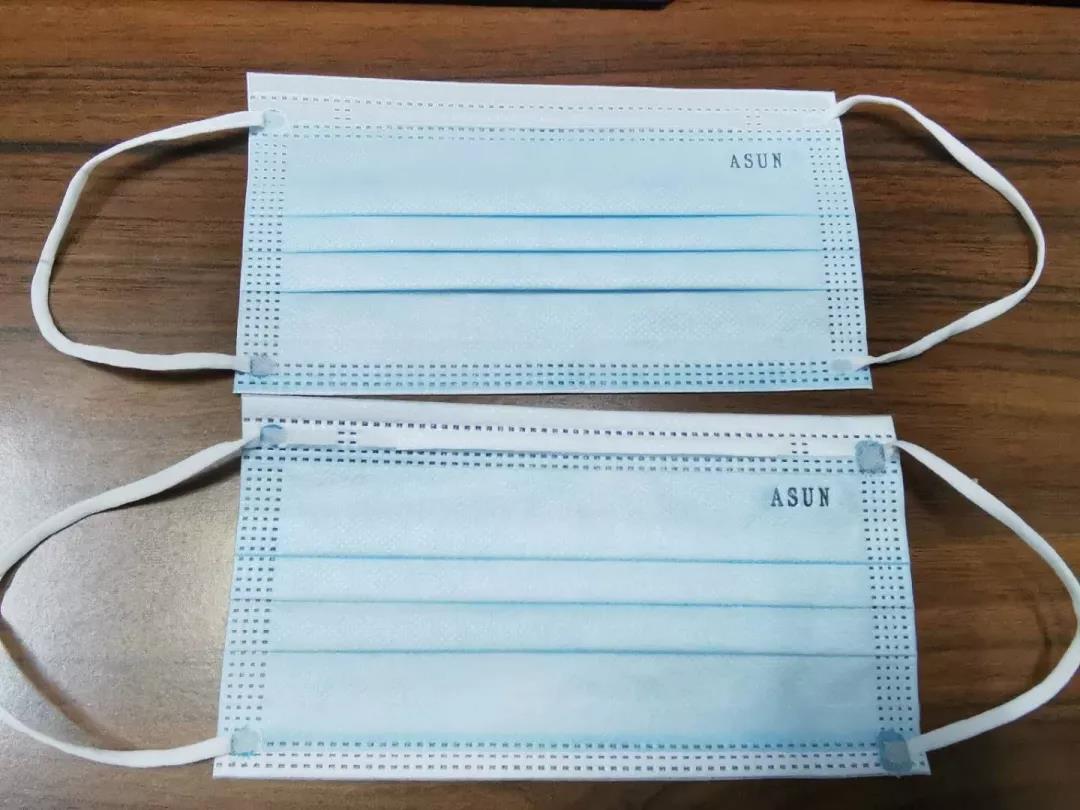

In June 2020, the first fully automatic mask production line was put into operation, which was fully standardized in accordance with The ISO13485 standard. The products have passed the TUV SUD PSB with EN 14683 test certification locally, all the test items (BFE, Microbial, Breathability and Splash Resistance) have reached the excellent level, which has been fully recognized by the Health Sciences Authority (HSA). It is expected that the second phase will be completed in August 2020, when the company will have two production lines and the monthly production supply will exceed two (2) million pieces, so as to fundamentally alleviate the shortage of masks.

Our main objective and contribution are to provide the best quality masks to safeguard society against the coronavirus and other viral infections.

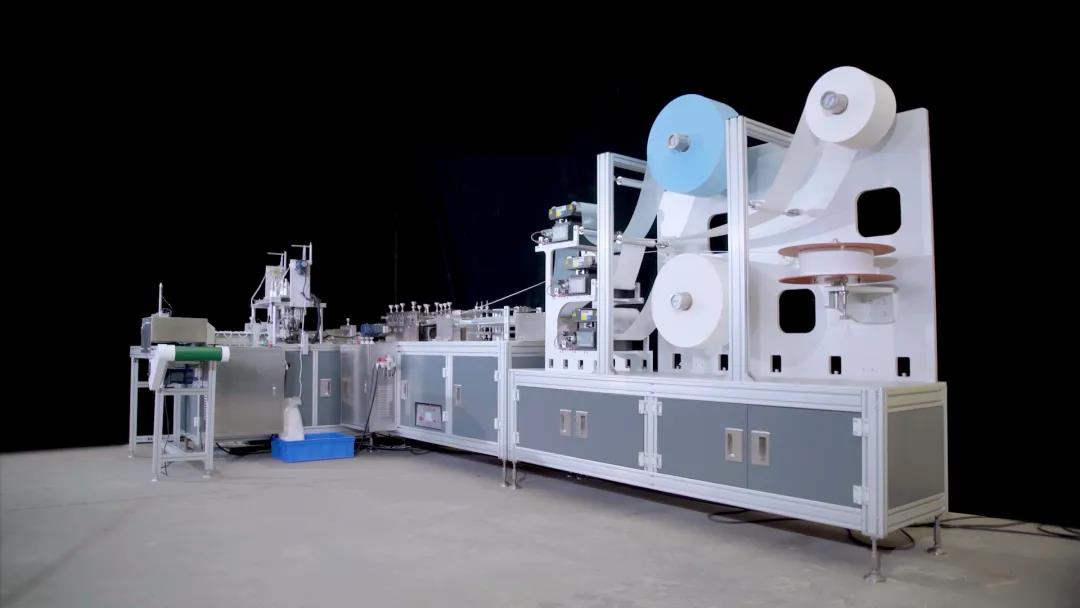

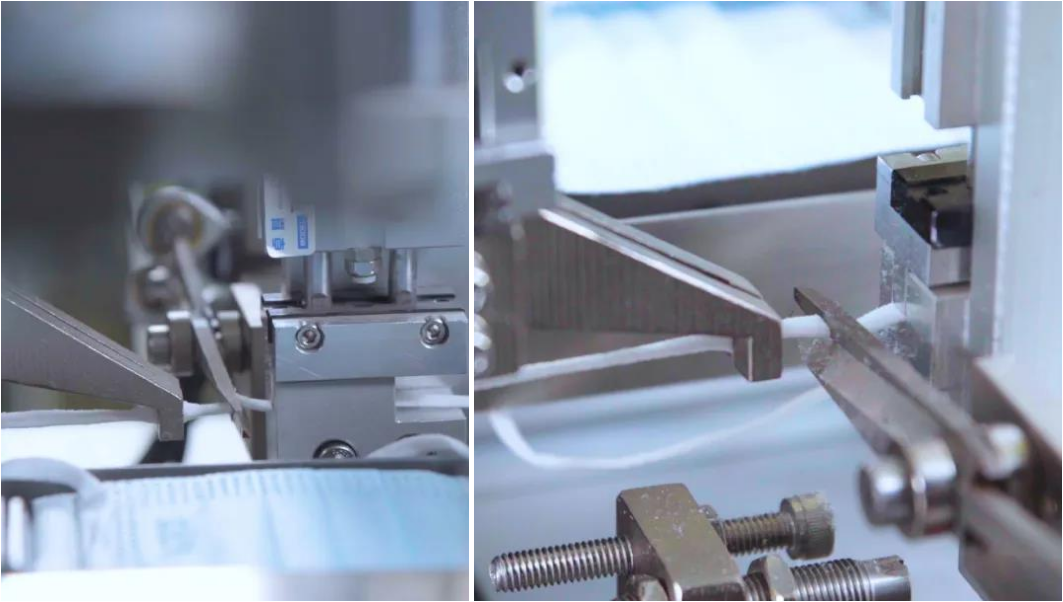

To use sliding differential axis mode on fabric feeding, and the 3 Layers fabric alignment system to optimize raw material width control and reduce the production cost.

The frequency control system combined with the automatic counter can keep track of the production status and adjust the equipment running speed in any time according to the production demand.

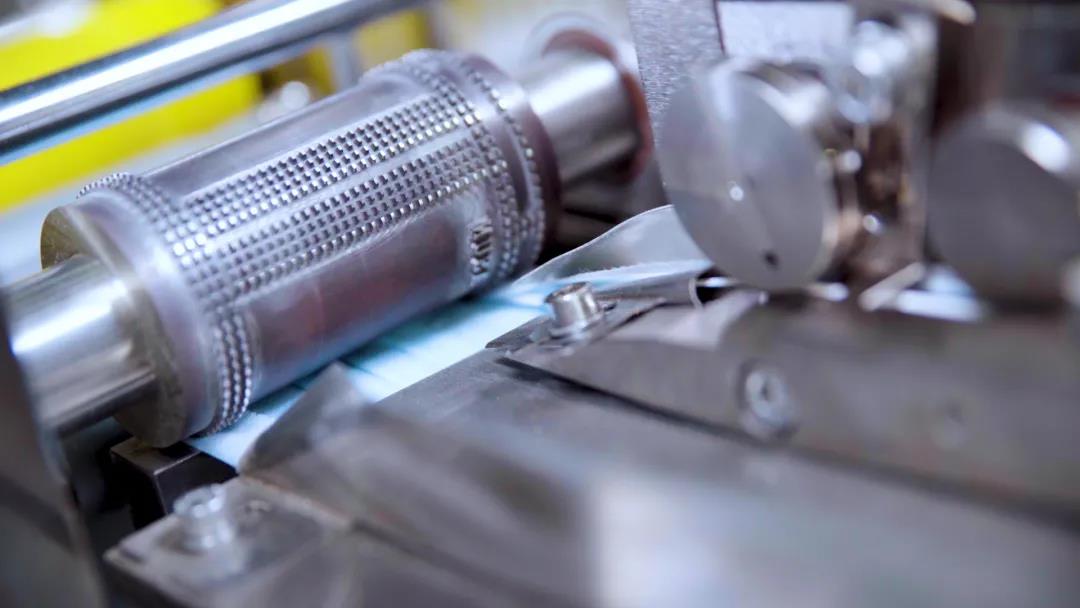

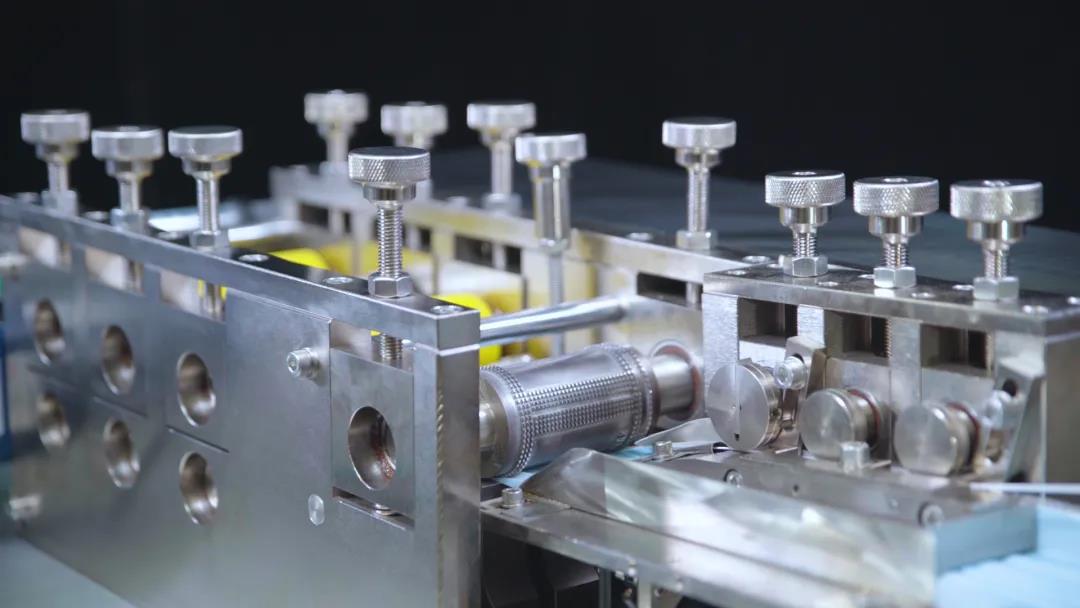

Ultrasonic seal and welding systems make the ear band feeding and welding more excellent. Use high-quality aluminum alloy Cr12MoV as the main material to ensure the whole system more reliable and longer life span.

| details |

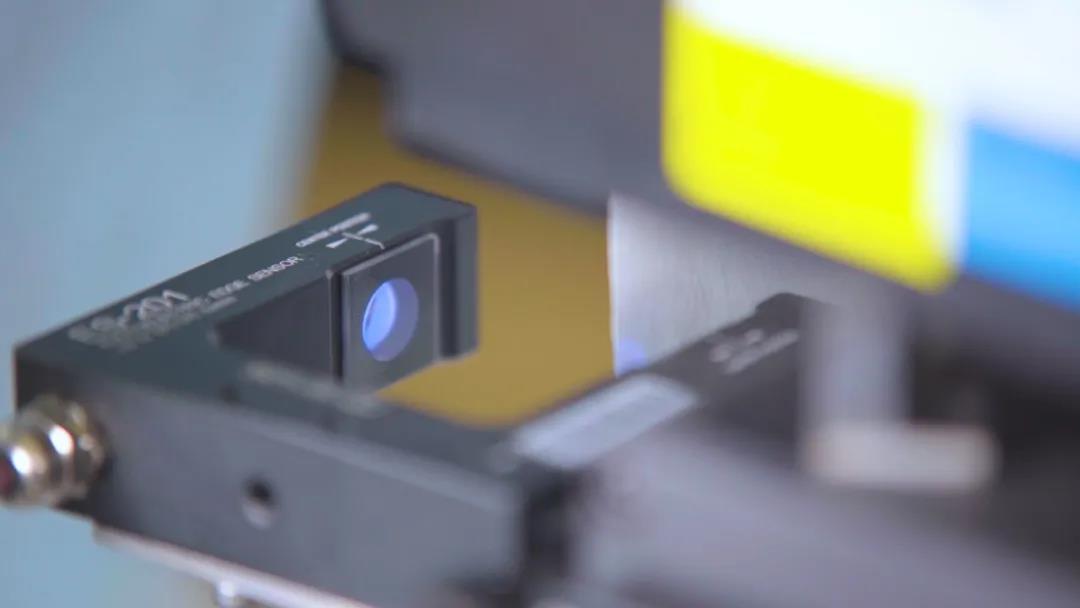

Automatic 3-Layer mask manufacturing line, with 4.75m x 2.15m x 1.85m dimension, convenient to customers to manufacture different types of products, the number of layers and fold position are adjustable to improv the efficiency of the production line, applied with professional PLC program control mode and photoelectric detection system, to ensure the final product quality even under long manufacturing time.

The masks produced by Asun automatic manufacturing line, adopt professional PP Meltblown Non-woven Fabric and ear loop design, to ensure the better filtration efficiency and more convenience and comfortable for wearing.

The masks can be adapted commonly for the users in the healthcare, electronic, mining, construction and other industries areas etc.