Designed by Asun International Pte Ltd, the Automatic 3-Layer Disposable Face Mask Manufacturing Line, is integrated automatically by roll material feeding and folding, nose clip insert, mask molding and cutting, ear band feeding and welding, final product UV Sterilization and checking etc. The main frame and component use aviation aluminum alloy and stainless-steel material, which are more reliable and without rust.

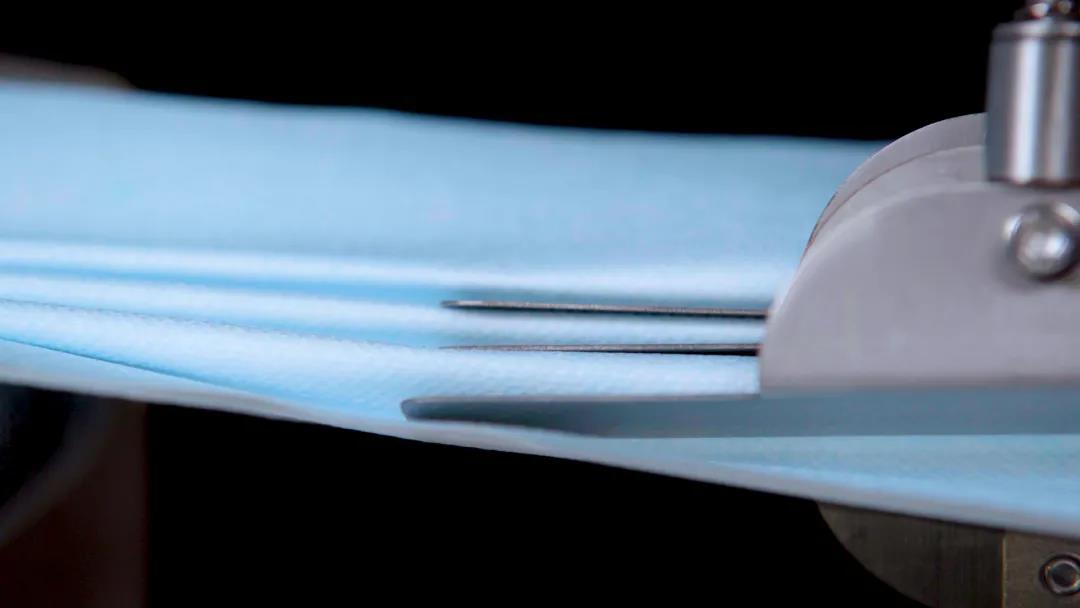

To use sliding differential axis mode on fabric feeding, and the 3 Layers fabric alignment system to optimize raw material width control and reduce the production cost.

The frequency control system combined with the automatic counter can keep track of the production status and adjust the equipment running speed in any time according to the production demand.

Ultrasonic seal and welding systems make the ear band feeding and welding more excellent. Use high-quality aluminum alloy Cr12MoV as the main material to ensure the whole system more reliable and longer life span.

Automatic 3-Layer mask manufacturing line, with 4.75m x 2.15m x 1.85m dimension, convenient to customers to manufacture different types of products, the number of layers and fold position are adjustable to improv the efficiency of the production line, applied with professional PLC program control mode and photoelectric detection system, to ensure the final product quality even under long manufacturing time.

The masks produced by Asun automatic manufacturing line, adopt professional PP Meltblown Non-woven Fabric and ear loop design, to ensure the better filtration efficiency and more convenience and comfortable for wearing.

The masks can be adapted commonly for the users in the healthcare, electronic, mining, construction and other industries areas etc.